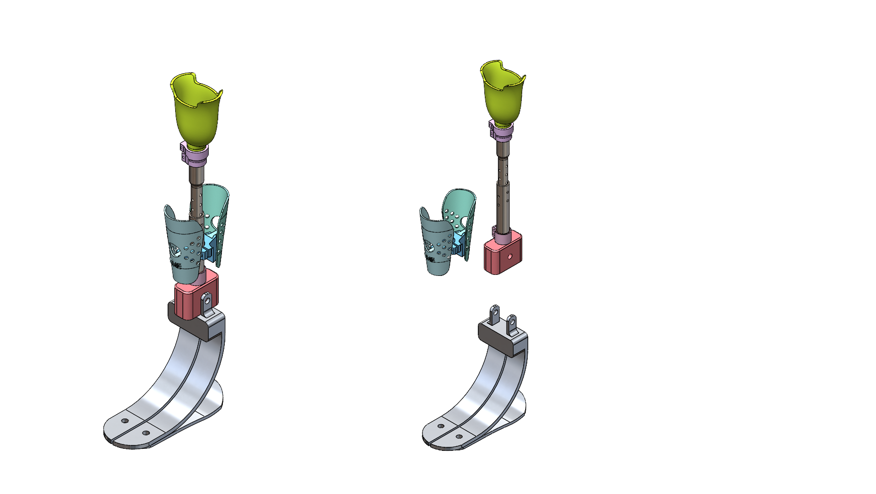

objective: design an open-source 3D-printable device used for stroke patient recovery.

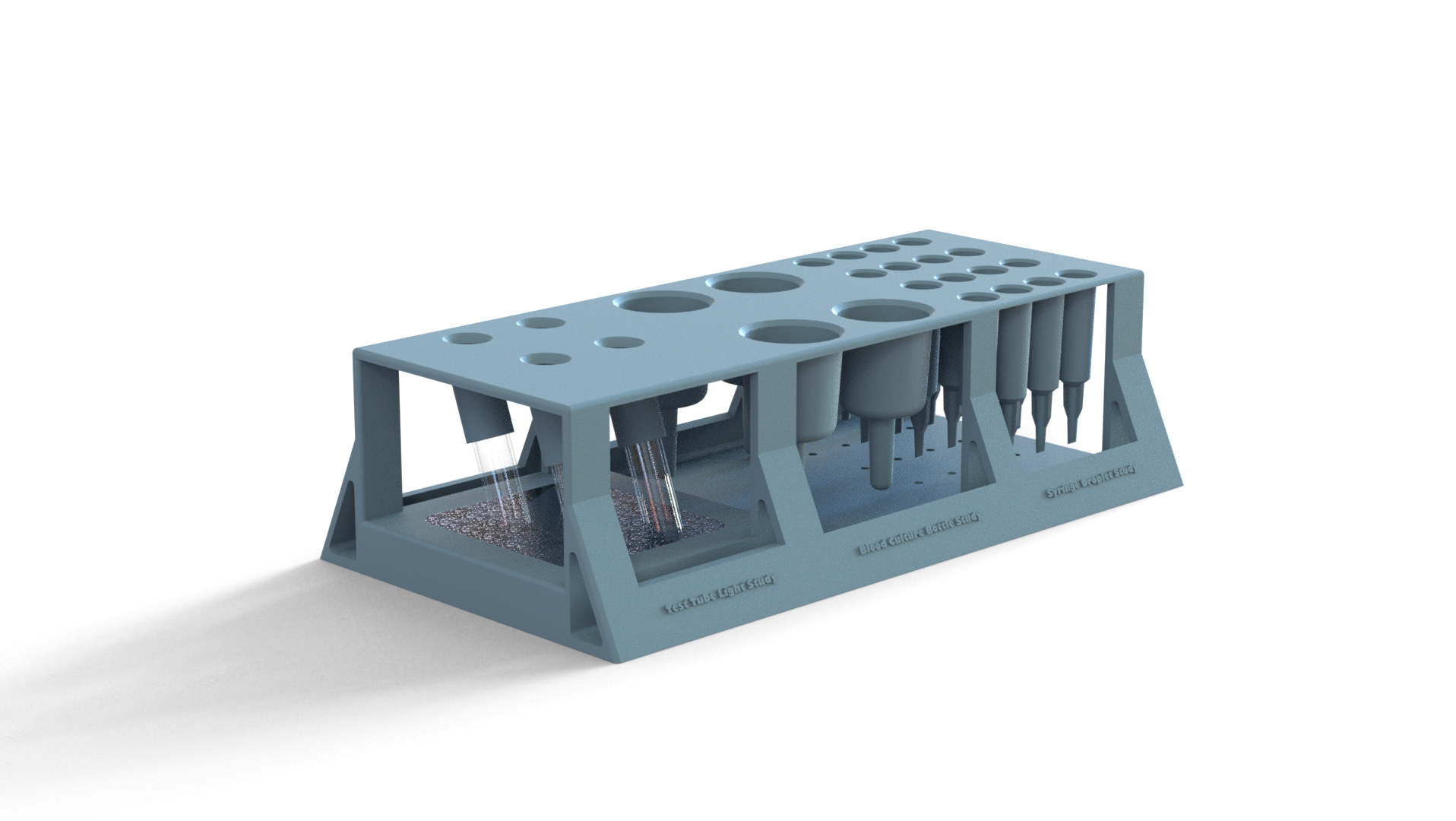

full assembly and drawings done on solidworks, with ultimaker cura used as slicing software for 3d printing.

bill of materials (BOM) for assembly made on solidworks.

final model manufactured and assembled, along with tested for functionality.

The orientation of the model on the 3d printer made huge differences in print time and whether support material was used. Support material was avoided in most models to reduce post processing time and resources.

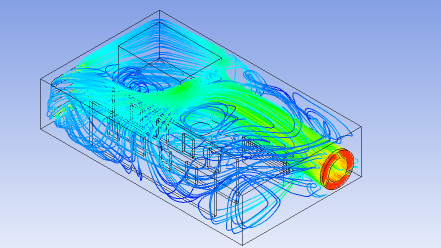

further development to parts could be made using topology optimization algorithm for achieving a more seamless and engineered model.